Bronze Floor Cavity Soundproofing System

System Overview

The Bronze Floor cavity soundproofing system reduces airborne noise when installed between the joists and is particularly useful if any increase in the existing floor height is not desired.

We are open Monday to Friday

Product Hotline - 01993 704 981

Local call rate - 0208 0909586

The Bronze Floor cavity soundproofing system reduces airborne noise when installed between the joists and is particularly useful if any increase in the existing floor height is not desired.

This Bronze Floor Cavity System is designed to improve the sound insulation of timber suspended floors so is not suitable for concrete floors. It is particularly useful if any increase in the existing floor height is not desired and will help reduce airborne noise from above and below. The system is also a very good prelude to further soundproofing that may be required on top of the floor to enhance the soundproofing properties of the insulated floor at a later date. This system is unlikely to reduce any footfall or impact sound that is made on the floor.

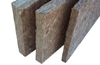

The main products used are our SoundBlocker Membrane and Acoustic Mineral Wool and installed as a sandwich (See Below).

SoundBlocker Membrane

This innovative material utilises synthetic rubber and special fillers producing a revolutionary acoustic membrane.

This innovative material utilises synthetic rubber and special fillers producing a revolutionary acoustic membrane.

This product is nominally 1mm thick and weighs just 2Kg/ m² so it’s easy to handle and carry in cut pieces. However a full roll is quite heavy and best handled by two people.

Acoustic Mineral Wool

The AMW is denser than normal loft insulation and due to the specific density is far more efficient at absorbing noise. Acoustic Mineral Wool (AMW) is used extensively in buildings and throughout industry to give acoustic, thermal and fire insulation. It is particularly useful as a sound absorbing infill between floor joists as part of a system to reduce airborne sound between separating floors.

The AMW is denser than normal loft insulation and due to the specific density is far more efficient at absorbing noise. Acoustic Mineral Wool (AMW) is used extensively in buildings and throughout industry to give acoustic, thermal and fire insulation. It is particularly useful as a sound absorbing infill between floor joists as part of a system to reduce airborne sound between separating floors.

It is non-flammable, chemically inert and is not adversely affected by any substance it may come into contact with. The panels are Zero ODP and Zero GWP in the terms of the code for sustainable homes. Each slab is made from 22% recycled raw materials.

Random arrangement of fibres resists water penetration in any direction. It is rot-proof, non-hygroscopic, does not sustain vermin and will not encourage the growth of fungi, moulds or bacteria. It will not react with wired plastic or metal wall ties, brickwork or masonry.

The system is supplied with the following products included;

A layer of SoundBlocker Membrane – (12m x 1.25m and 1mm thick) per roll

2 x Layers of Acoustic Mineral Wool – (1200mm x 600mm x 50mm thick) per slab

If you have experience of lifting floorboards then the system will be easy to fit otherwise a local handyman or second fix carpenter could undertake the work.

Once ordered the products are all delivered to your door (Access Permitting) with full step by step install instructions.

Work out the area of your floor then use our product selector below to work out how much you need. Give us a call on 0845 363 7131

|

YOUR FLOOR Area in m2 |

Soundblocker Membrane

|

Acoustic Mineral Wool 50mm thick (Enough for 2 layers) |

|

1

|

1

|

3

|

|

2

|

1

|

6

|

|

3

|

1

|

9

|

|

4

|

1

|

12

|

|

5

|

1

|

14

|

|

6

|

1

|

17

|

|

7

|

1

|

20

|

|

8

|

1

|

23

|

|

9

|

1

|

25

|

|

10

|

1

|

28

|

PLEASE NOTE: The figures above are based on the whole floor area and do not allow for the joists widths. This may mean the figures quoted for Acoustic Mineral Wool maybe slightly higher than needed and as we don’t know many floor joists your floor has the figure given for SoundBlocker Membrane may be not enough as the product goes up and over the joists. We advise you check this yourself before ordering.

We advise to always add a few extra of each product to allow for wastage from offcuts.

Please note: This system is effective at reducing normal noise levels, that should not normally be heard, for example normal talking and radio sound. We suggest you also use a suitable system on top of the floorboards for more beneficial sound insulation. Music and bass noise will always be audible although its intensity should be reduced as long as the sound insulation is correctly installed.